Published on October 27th, 2022

Last updated on February 3rd, 2023

How To Cut Acrylic Sheet?

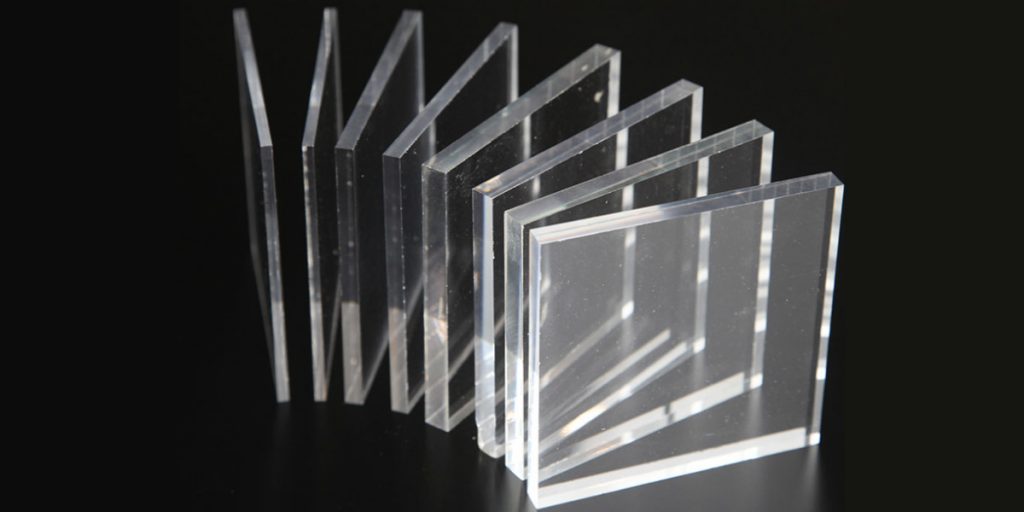

Organic glass is one of the most popular construction and decorative materials. Due to its technical characteristics, plexiglass is widely used in industry, construction, and everyday life. The domestic use of acrylic glass is very varied – people use it to make souvenirs, trinkets, business card holders, decorative elements, lamps, aquariums, and much more. Such widespread use of plexiglass in everyday life is due to its high strength, low weight, attractive appearance, and ease of processing.

Home handyman has to deal with different materials. In this case, we face with the question: how to cut plexiglass at home into pieces of different sizes and thicknesses. It is good when there are special tools for processing each. But this is not always the case. More often, the already available universal set is used. In this article, we will tell you how to do it and what tools are better to use for cutting plexiglass.

What are the features of acrylic sheet cutting?

Acrylic glass is called plastic and is obtained by mixing methyl acrylic acid with ester components and their subsequent polymerization. People can call it acrylic or plexiglass. It is just as transparent as glass but weighs less. When heated to 90-100 °C, the material becomes malleable. You can bend it to give it the desired shape. Take this feature into account during processing. When heated, it is easy to deform or cut plexiglass.

Acrylic begins to melt at 160 °C. The power tool blade heats the workpiece as it is being cut. The temperature gets over the melting point reasonably quickly. Plexiglas melts, and its particles stick to the cutting unit, which makes it challenging to work. Therefore, it is desirable to use cooling. So, blowing with a jet of cold air or water is carried out in production.

What tools and rules do you need for the easiest way to cut plexiglass?

To cut a piece quickly and accurately, you must follow a few rules you should learn before doing the job. They “work” for most synthetic materials: organic glass, polycarbonate, and others. Let’s list the basic rules for cutting at-home acrylic sheets 4 mm and other sizes:

- Straight or curved cuts are much easier to make if the part is heated. To do this, you can warm it up a little before the processing. Use a construction hair dryer or a gas burner as a heat source. Keep the latter at a distance from the heating device not to melt the acrylic.

- For work, it is best to choose a blade marked. It is hardened steel of high strength.

- You can do sawing with any power tool only at low speeds. Otherwise, the acrylic glass will get hot from the blade and melt. Select the speed for each tool individually.

- You cannot cut the plexiglass without eye protection. It is necessary to wear a mask or special glasses. Working produces many sharp, small splinters that fly out from under the cutting assembly.

After carefully studying the rules, you can learn what tools you can use to cut acrylic sheets. There are many options for cutting plexiglass 2 mm and thicker at home. Let’s look in detail at the most effective and easily accessible.

1. Hacksaw

Plexiglas is comparable to beech in hardness and processing difficulty. The best way to cut acrylic sheet includes a hacksaw or a homemade cutter made of cutting cloth if the work is minor. For processing, choose a blade with frequent fine teeth. Then follow the next instructions:

- Firstly, mark the workpiece, and spend a cut line on it. Most often, it is a straight line. It is challenging to cut a curvilinear part with a hacksaw. Mark it with a felt-tip pen or a marker. It leaves a clear mark.

- Scratch a line with a sharp nail or a knife.

- It is necessary to saw slowly, not allowing intense heating of a part.

- To prevent the blade from sticking, we recommend pouring cold water over the acrylic sheet cutting area periodically.

The cut from the hacksaw is uneven and requires finishing by sanding.

2. Cutter

It is convenient to use with small amounts of work when the thickness of the sheet does not exceed 2-3 mm. You can find it in hardware stores. With its help, straight cuts are performed, and curved cuts are difficult to do. Next, your steps will be as follows:

- Before cutting, mark the acrylic sheet.

- Then firmly press the metal ruler to the marked line. With effort, spend a cutter on the sheet. Do it a few times to get a kerf about half the depth of the plate.

- Then, put it on the edge of the table or workbench and break off the edge with a precise movement.

- The cut is uneven, so it is sanded afterward. Use a homemade cutter from a hacksaw blade for metal. You have to take the blade on a grinding wheel to sharpen it, so it is convenient to saw.

- The opposite edge will be the handle. It is wrapped with duct tape.

- The easiest way to cut plexiglass with a homemade cutter is ready. Use it the same way as with a hacksaw.

3. Jigsaw

You should choose only a jigsaw with adjustable speed for work. It is best to take jigsaws for metal, but if it is impossible, wood blades will do. In this case, they should be with fine and frequent teeth. Electric jigsaw can perform not only a straight plexiglass cut but also curvilinear. True, it will not be easy to do this. You can follow these rules to ensure a good result:

- You need to draw a line along which you will cut and run the tool. Select the smallest revolutions and the minimum speed.

- Try to move slowly so that the saw does not get hot. If there are signs of material melting, stop the work, and pour cold water on the kerf. It is simple to notice the melting. The plastic in the acrylic sheet cutting area of the cut becomes milky white, with smoke and a characteristic smell.

4. Nichrome wire

It is also one of the best ways to cut acrylic sheet. It is used to make curved vertical and straight horizontal cuts. To do this, you need to use a homemade device:

- Nichrome wire is connected to a current source, and the voltage is 24 V. It is desirable to use a rheostat to regulate the heating.

- Fix the thread on both sides to look like a torch. Sometimes you can attach a handle to the upper end and attach a weight to the lower end.

- Such a device is convenient for performing curved vertical cuts and cutting complex shapes.

5. Laser systems

You can use laser systems for complex and high-precision cutting and also for cutting acrylic sheets. A laser cutter connected to a computer works like a printer to transfer the design/picture onto a sheet of acrylic. A laser is the best option if you need to create complex, intricate, and creative shapes out of plastic. How to use it:

- Before plexiglass cutting with a laser, it is important to have a good vector model. It can be created in any of the different vector graphics software tools. To prepare it, you also need to know the program in which the machine is running. Most programs work in RGB mode and millimeters. In this case, the color of each line should be specified by the manufacturer, and the pitch should be 0.01 mm.

- If you need to cut many parts of an acrylic sheet, the best way is to keep them as close to each other as possible (usually limited to 2 mm between components, but it depends on the thickness of the sheet).

- If the model has text, only the outline will be cut. Letters with space inside (e.g., A, O, B) should have a link that connects the inside and outside space. It is worth considering that sharp corners can break if you plan to cut thin sheets. The solution is to add a small hole in each sharp corner. It will distribute the stress over the entire surface.

6. Electric milling machine

You can make a quality smooth plexiglass cut with a router, but the cutting unit is quickly triggered. One of the best ways to cut polymers is with a finger or disc cutter. If you choose the right cutter for acrylic, the edge is straightforward and does not require polishing. However, there are both advantages and disadvantages. The pros include speed and accuracy of cutting, and the absence of internal stresses after processing. Among the cons are the thickness of the cut, the actual diameter of the cutting tool, which “decides” the material and turns it into chips. Also, the accuracy of the cut is limited by the mechanics and thickness of the cutter, the cut can not be less than 1 mm.

For acrylic sheet cutting, choose a millimeter-thick cutter. Another disadvantage is strong smoke when working because acrylic gets hot. Without cooling, it can not only melt but also foam. Therefore, it is necessary to bring water to cool the cutting area. The easiest way to feed the coolant is from a plastic bottle with a small diameter tube inserted in the stopper. In this simple way, you can achieve a precise and even cut.

Bottom Line

Cutting organic glass at home is a relatively simple operation that you can perform with the help of handy tools. Your home can get messy after slicing acrylic, as with any renovation, so it’s important to know quick cleaning tips. So, whenever you decide to cut plexiglass and other materials, you should always take precautions. Attach the sheet of plastic to the workstation with clamps so that it doesn’t shift during cutting, and wear safety glasses to protect your eyes from accidental pieces. It is necessary to pay attention to the thickness of the sheets, the presence of curvilinear elements in part, and a set of tools available to the home craftsman to determine how and what to cut plexiglass with. There is the use of a cutter and nichrome thread, and the easiest way to cut plexiglass is cutting with a hack.

FAQ

Can I cut plexiglass with a bolt cutter?

Experts recommend doing it only if the sheet is thick enough. Its thickness should exceed 5 mm. Only straight cuts are performed with a grinder, curvilinear cuts are impossible. The tool cuts quickly, and acrylic glass has no time to overheat and melt.

What kind of disk to cut acrylic?

The temperature of acrylic mustn’t rise. It does not start to melt and stick to the disk. It can be used to cut sheets up to 10 mm. When you decide how to cut the material, use a three-toothed blade.

What cutter should I choose for cutting acrylic sheet?

When working with different types of plastic and acrylic, one- and two-step cutters are more often used because they have a larger width of grooves for chip evacuation. The cutter doesn’t get clogged and the cutting speed and cleanliness increase.

What kind of laser cuts acrylic?

Acrylic can be cut or engraved with a CO₂ laser or marked with a fibre laser. But you must also pay attention to the thickness of your sheet and its composition. Some lasers have limitations.